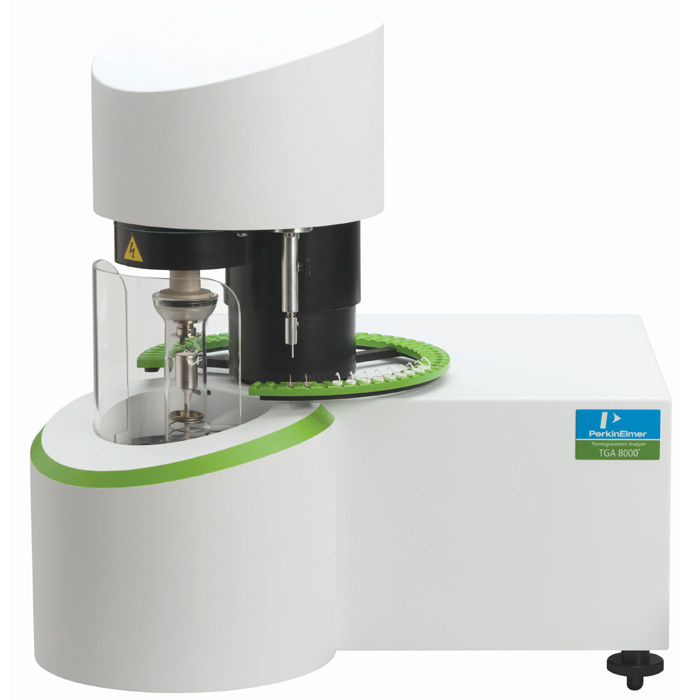

Thermogravimetric Analyzer

Thermogravimetric Analyzer

| FABRICANT | PerkinElmer |

|---|---|

| MODÈLE | TGA 8000 |

On this TGA, an optical null ultra-microbalance, isolated in a temperature-compensated balance chamber, ensures stability and provides the capability of measuring the smallest weight changes. With its two integrated mass-flow controllers, it is possible to purge the furnace (sample) and the balance with distinct gases. Its low mass and forced-air cooling allow it to cool quickly for fast sample turnaround. The TGA 8000 permits the analysis of volatile and humidity/air-sensitive samples through the Accupick accessory. The accessory has a needle that is attached to a stem fixed under the balance system of the TGA. When the autosampler is raised, the needle punctures the cover of the Accupik pan (made of aluminum). The pan capacity is about 30µL and is suitable to liquid and solid samples.

The TGA 8000 permits the study in a wide array like the decomposition and thermal stability, the component identification and quantification, the moisture/solvent evolution and identification and the study of reaction kinetics.

Technical specifications:

Balance Performance:

o Sensitivity: 0.1 µg

o Capacity: 1300 mg

o Accuracy: better than 0.02%

o Precision: 0.01 %

Temperature Specifications:

o Range: ambient to 1200 °C

o Scan rates: 0.1 °C/min to 500 °C/min

o Precision: ±1 °C

Cooling Method:

o Forced air cooled with an external fan.

o Cycle time: 1100 °C to 50 °C in less than 13 min

Atmospheres: argon, helium, nitrogen

Autosampler: 48 positions

Advanced modes:

o AutoStepwise TGA: automatically determines start and end points of

a weight loss and switches between various heating rate and isothermal steps to optimize analysis.

o Variable Rate TGA: continuously modifies heating rate based on

the rate of weight loss to improve resolution of overlapping weight loss processes.

o TGA Decomposition Kinetics: provides the capability of determining the kinetics of decomposition based on TGA data taken at several (3 to 6)

heating rates.

To use this equipment

The equipment available is accessible to the academic and industrial research community.

To learn about usage conditions and availability, please fill out the form below. After reviewing your request, we will contact you shortly to offer you the best available solution.